Production of green hydrogen / green methanol

Sewage sludge is currently mainly a disposal, applied to fields as fertilizer or used in co-combustion or mono-combustion.

The use of sewage sludge as fertilizer on agricultural land is increasingly being regulated and is to be completely phased out in the medium term.

Now PH2 has developed a disruptive plant that produces either green hydrogen or methanol from sewage sludge.

This turns the problematic sewage sludge into green energy, cost-efficiently and at market prices.

Generation of green energy from sewage sludge

In addition to the sewage sludge drying module PH2 optionally offers a further module for the production of either green hydrogen or green methanol.

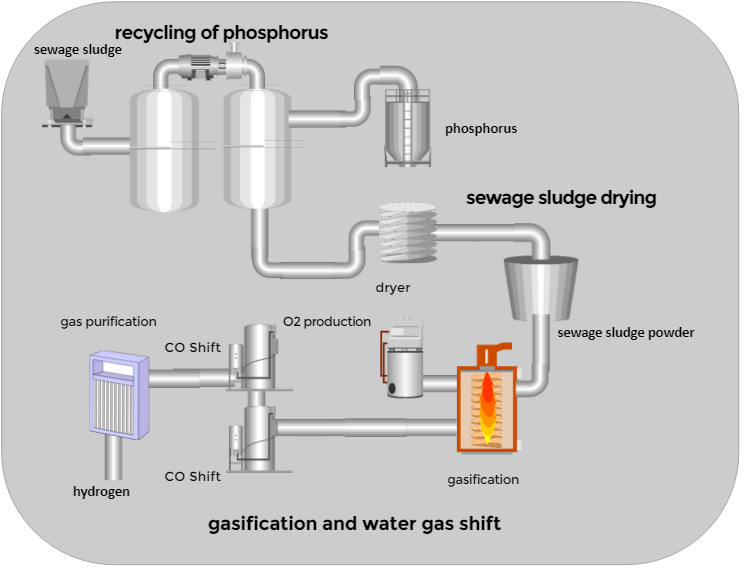

Sewage sludge powder is produced via the PH2 sewage sludge drying system. This is converted, depending on the plant type, energy efficiently into either green hydrogen or methanol in a gasification process with subsequent reforming.

A module developed by PH2 for the innovative recovery of phosphorus can optionally be integrated in advance of the sewage sludge drying process.

The fully expanded system developed by PH2 consists of three modules: Phosphorus recovery, sewage sludge drying and production of green energy (green hydrogen or methanol).

The PH2 process turns sewage sludge from a problematic substance into a valuable source for green energy.

Fossil resources are conserved, energy is generated from waste materials.

The production costs for green hydrogen from sewage sludge are between 0.60 €/kg and 2.00 €/kg, depending on the size of the plant.

The process is CO2-neutral and largely non-toxic.

The residue that remains after the phosphorus recovery and the gasification process is slag with a low proportion of heavy metals, the volume is depending on the proportion of sand in the sewage sludge.

Competitive costs

The modular design of the system increases flexibility and a decentralized location for green hydrogen production is easily possible.

Plant diagram

for energy- and cost-efficient generation of

green hydrogen from sewage sludge

Our PH2 expertise:

Phosphorus

Sewage slugde

Green hydrogen

Your questions about GREEN HYDROGEN

What types of hydrogen do exist?

Depending on the production methods used to obtain hydrogen the hydrogen types have different colour names. Green hydrogen is produced by electrolysis using electricity from renewable energy sources. Turquoise hydrogen is produced by methane pyrolysis. Grey hydrogen is produced by steam reforming fossil feedstocks such as natural gas, coal or oil. Blue hydrogen is produced like grey hydrogen but the resulting CO2 is stored underground. In addition there is also pink or yellow hydrogen. This is also produced by electrolysis but by means of electricity generated from nuclear power.

What is green hydrogen?

Hydrogen and methanol are currently mainly obtained by reforming natural gas. They therefore have a fossil origin. Green hydrogen and green methanol are produced without the use of natural gas. The technologies used to produce green hydrogen are very diverse. Hydrogen can be produced with green electricity by electrolysis from water. Another method is the production of hydrogen by a plasma process that requires very high temperatures. Alternatively hydrogen or methanol can also be produced from a synthesis gas by steam reforming. This is the process of PH2 Technology GmbH. If the used raw materials have a biogenic origin (biomass, sewage sludge) the produeced hydrogen / methanol is green hydrogen / green methanol.

When is green hydrogen produced?

Green hydrogen is produced in a wide variety of processes. It is essential with which energy source the hydrogen is produced and from which substances the hydrogen is produced. The electrolysis of water with wind energy produces green hydrogen. Green hydrogen is also produced during the recycling of sewage sludge or biomass in the plants of PH2 Technology GmbH.

Why is green hydrogen so expensive?

Green hydrogen is currently expensive because green hydrogen is predominantly produced with electrolysis and the cost of electricity makes hydrogen expensive. Another cost factor are the high transport costs. A 40 t trailer with hydrogen can transport just 300 kg of hydrogen. The PH2 Technology GmbH produces hydrogen decentrally with its plants and uses a process that is many times cheaper than electrolysis. The price of hydrogen from the large plants of PH2 Technology GmbH is lower compared to the price from the production with natural gas reforming.

How much electricity is needed to produce 1 kg of green hydrogen?

It depends on the procedure. With electrolysis the electricity requirement for 1 kg of hydrogen is about 40 – 55 kWh. The PH2 Technology GmbH process requires approximately 5 kWh per 1 kg of hydrogen.

When will green hydrogen and power-to-gas become economical?

Green hydrogen and power-to-gas will become economical with the commissioning of the hydrogen plants of PH2 Technology GmbH. The plants can produce hydrogen at production costs of € 0.60 to € 2.00 per kg. This is the range of today’s production costs of hydrogen from natural gas. The planned commissioning of the first plant is scheduled for 2027. Under today’s conditions hydrogen from electrolysis can only become economical in island operation. Here the legislator would have to change the legal framework.

How can green hydrogen in refineries contribute to climate protection in transport?

Green hydrogen is an essential component for the energy transition. We must take advantage of all opportunities for decarbonisation. Green hydrogen can be used to generate heat at very high temperatures. Green hydrogen has the potential to be used as a fuel for heavy goods vehicles and car traffic over long distances. Hydrogen is also an important raw material for the chemical industry.

Why does Germany want to get into the production of green hydrogen, even though it has no electricity “left”?

Electricity cannot currently be stored in large quantities. Since Germany has the highest energy consumption in winter it is necessary to store the energy generated in the other seasons. The energy can be converted into hydrogen and reused in winter. With the expansion of renewable energies from solar energy and wind power the number of days with electricity surplus will increase. The aim is to generate enough electricity to cover the energy demand on an annual average. Then Germany would be energy independent.

Hydrogen as an energy supplier – what opportunities and risks does it hold?

Hydrogen can be an important building block for our energy supply. However it does not make sense to rely on hydrogen as the only energy carrier. The technologies for the use of hydrogen are very diverse. Hydrogen from electrolysis is currently the preferred technology. However, it is also possible to produce hydrogen via solar thermal energy, plasma lysis or from biogenic waste by gasification. The possibilities of a hydrogen economy are very diverse, as hydrogen can be used both as a storable energy carrier and as a raw material for the chemical and pharmaceutical industry. The risks of hydrogen are rooted in its great chemical reactivity. Therefore extensive safety standards must always be consiered when using hydrogen.

Green hydrogen – the energy carrier of the future?

Green hydrogen has several important functions. It is an important energy source as a buffer for green energy. The second important function of green hydrogen is to replace oil and natural gas for the chemical industry. In the next few years we must succeed in replacing fossil fuels and building a CO2 circular economy.

What does green methanol mean?

Green methanol is methanol which is produced from renewable energy sources.

How to produce green methanol?

Methanol is currently reformed mainly from natural gas. Green methanol is obtained from a synthesis gas produced during the gasification of biogenic waste or sewage sludge. This gas is fed to steam reforming with a catalyst. Depending on the catalyst methanol or hydrogen is produced during steam reforming.

How much does a litre of green methanol cost?

The current price and price development of methanol can be found on the website methanol.org. The market for green methanol is currently still too small for official pricing. In the medium term it must be possible to produce green methanol at prices of methanol from natural gas reforming.

Is green methanol the energy source of the future?

Methanol can be used as a liquid energy carrier. However because of the toxicity of methanol higher safety requirements are required than for example gasoline. Methanol is an important raw material for the chemical industry.